In this section, we describe how the entire production cycle of Tapis Rouge‘s handmade and hand-knotted rugs unfolds, detailing each phase: from selecting fibers and blends, to spinning, dyeing, rug making, and finishing. The final stage allows us to achieve the desired textures and design details at various pile heights.

OUR PRODUCTION PROCESS:

- Concept & Design

- Sample Drawing

- Thread Confirmation

- Yarns preparation and dyeing

- Knotting

- Pre-washing

- Knot leveling and Stretching

- Carving and Finishing

Concept & Design

We draw inspiration from various sources, be it nature’s enchanting beauty, architectural

masterpieces or research into the rich tapestry, fabric archives and cultural heritage. Each pixel is translated into a knot combining identities of the past with possible future scenarios.

Sample drawing

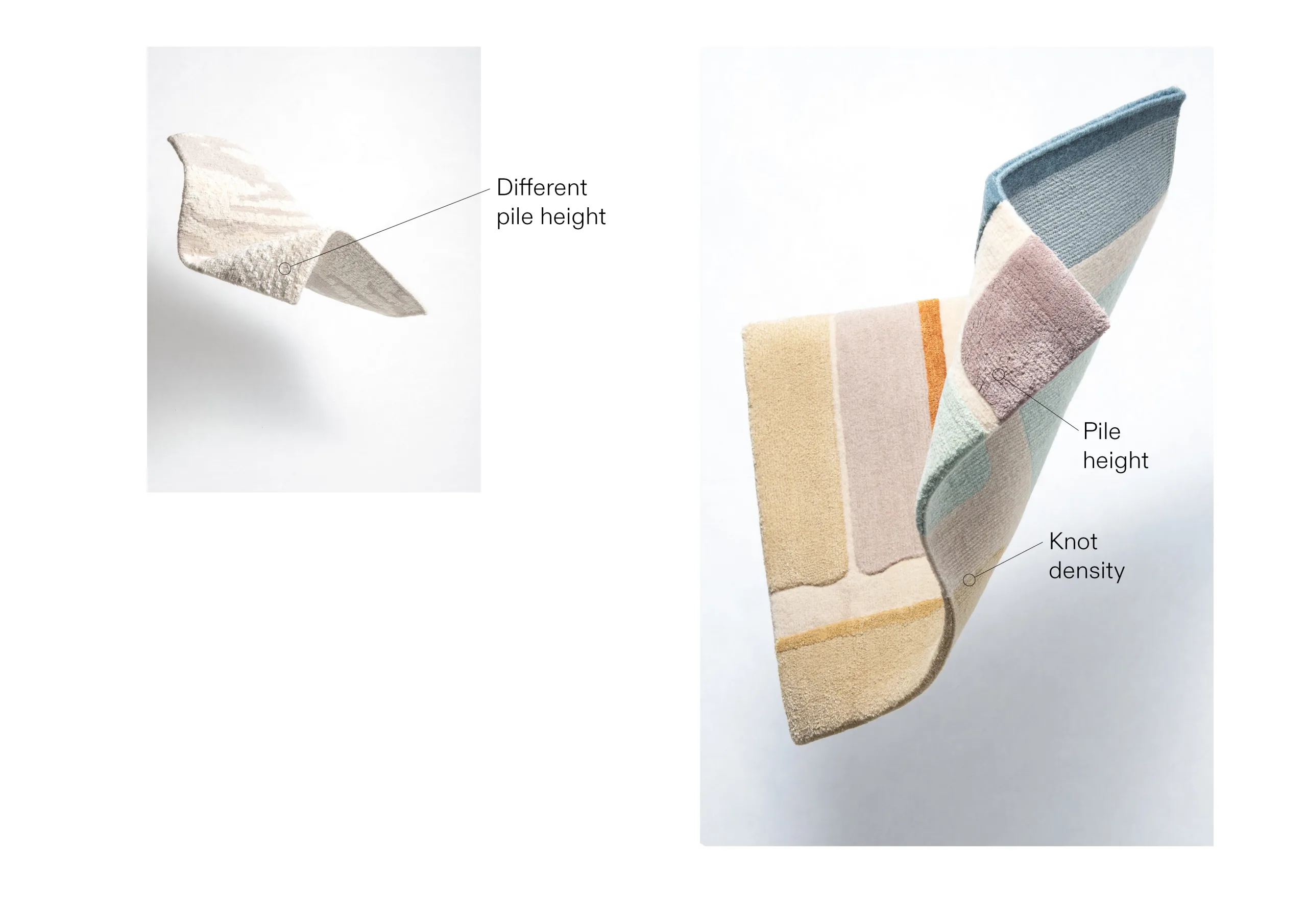

From gradients to the finest lines or different pile height, every new design is a wonderful

creation. We offer a wide range of carpet samples, allowing our clients to see the small details before ordering a full-size carpet or a custom design.

Thread Confirmation

Our production is sustainable and handcrafted with individually colored threads.

Once the colors are confirmed by our designers the production can be started.

Yarns preparation and dyeing

Our ethical commitment is intrinsic to preserving authentic, traditional processes from the past, that’s why we continue to use natural formulas that eliminate the environmental impact of dyeing the yarns.

Knotting

We knot stories, tradition, research, and innovation.

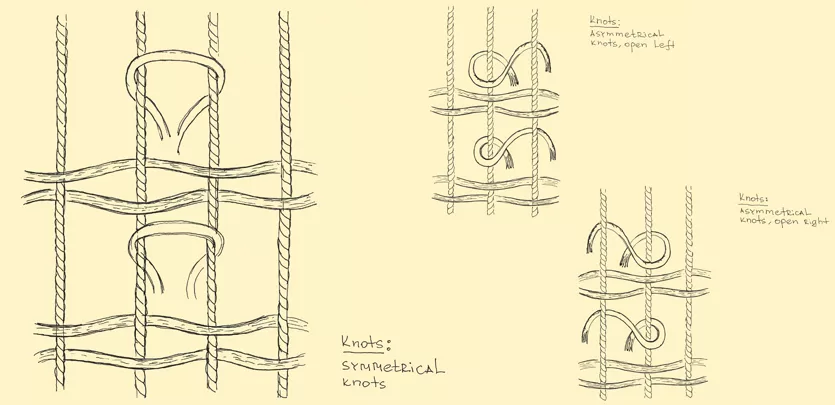

Hand knotting is a thousand-year-old art in the carpet production cycle; it brings a rich history and a profound meaning. The carpet fibers are fixed between the knots of the most intricate designs, often wool, silk, bamboo silk, or a blend of yarns that give robust, long-lasting textures.

Knots are the heritage of different cultures and techniques, a mixture of history and innovation that today testify to a legacy.

Today’s dedication of the artisans, the production time, and the knots density can support new product functions as an extension of this knowledge.

Hand-knotting

A precise manual weaving technique involving vertical or horizontal looms, a contraption of carefully selected materials, typically made from sturdy wood, which forms the foundation for the entire production process. Skilled artisans meticulously tie individual knots by hand, each securing a fiber strand into the rug’s weft threads. This technique permits various finishes, from simple to elevated loop piles to combining different and multiple natural fibers like wool, silk, and bamboo silk, each possessing unique characteristics that contribute to the final product’s texture and durability.

Combining different fibers adds depth and richness to the design, creating a visually stunning and tactilely pleasing rug.

Hand-tufting

A rug-making technique produced by master artisans employing specialized handheld tufting guns or needles. These tools enable controlled yarn insertion through a meticulously stretched canvas, tightly fastened to a robust frame.

As the yarn is intricately pushed through the canvas, it forms loops or piles on the rug’s surface, enabling artisans to craft distinctive textures and patterns.

The depth of intricacy within the design is calibrated through the manipulation of knot density. This parameter dictates the number of yarn loops per unit area, ranging from sparse, open designs to densely packed, plush patterns.

Knot density is a pivotal technical aspect that artisans carefully adjust to attain the desired visual and tactile effect. The palette of colors chosen for the yarn also plays a central role, offering an extensive spectrum of creative possibilities. Compared to other methods like hand-knotting, the production timeline for hand-tufted rugs is relatively shorter. However, it remains a time intensive process due to the manual nature of the technique.

Hand-tufted rugs often require skilled labor and premium natural materials.

Pre-washing

After the rug is hand-knotted, we wash it with special equipment, before stretching it for drying.

Knot Leveling & Stretching

To ensure that the pattern lines are exactly as on the sketch, an alignment and stretching step is necessary in the production process of our rugs. This process is carried out by master craftsmen, as it requires high precision.

Carving & Finishing

This is one of the most important and exciting stages in which the design comes to life, revealing its different volumes, shadows, and pile heights through the carving.